RM-RDD (ACFM) Rail Defect Detection

Rail Surface crack detection trolley based on ACFM technology

(Form of Eddy Current technology configured in a particular way to enhance the inspection of ferritic metals including welds).

Product description:

Rail rolling contact fatigue damage (RCF) in the form of rail surface cracks of the order of mm’s in depth can cause for serious safety hazards and potential rail breaks. It is therefor important that such defects which initiate from the rail surface are detected and sized in an early stage.

The RDD portable rail defect detection trolley is easy to carry and set up and is suitable for detecting rail surface cracks wit h length and depth measurement.

RDD

Applications:

- Detection of rail surface cracks with length and depth measurement

- For single and dual rail measurement of rails in tracks and switches

Main characteristics:

- Measurements that are highly accurate and repeatable

- Relatively simple installation and setup

- No requirement for on site calibration (less room for operator error)

- Works through air, paint, water and grease (less rail cleaning requirements)

- Full record of data (irrespective of whether defects are found)

- Suitable for any track gauge

- User friendly software for acquisition and review of measurement data

- Operation through notebook or tablet pc

- Robust yet light weight design

- Extensive product support

TECHNICAL DATA RDD

| # probes/sensors | Single rail: 1 shaped probe profiled to wheel shape (16 sensors per probe) Dual rail: 2 shaped probes (1 each rail) |

| Operating temperature range | -20 to +40 degrees Celsius |

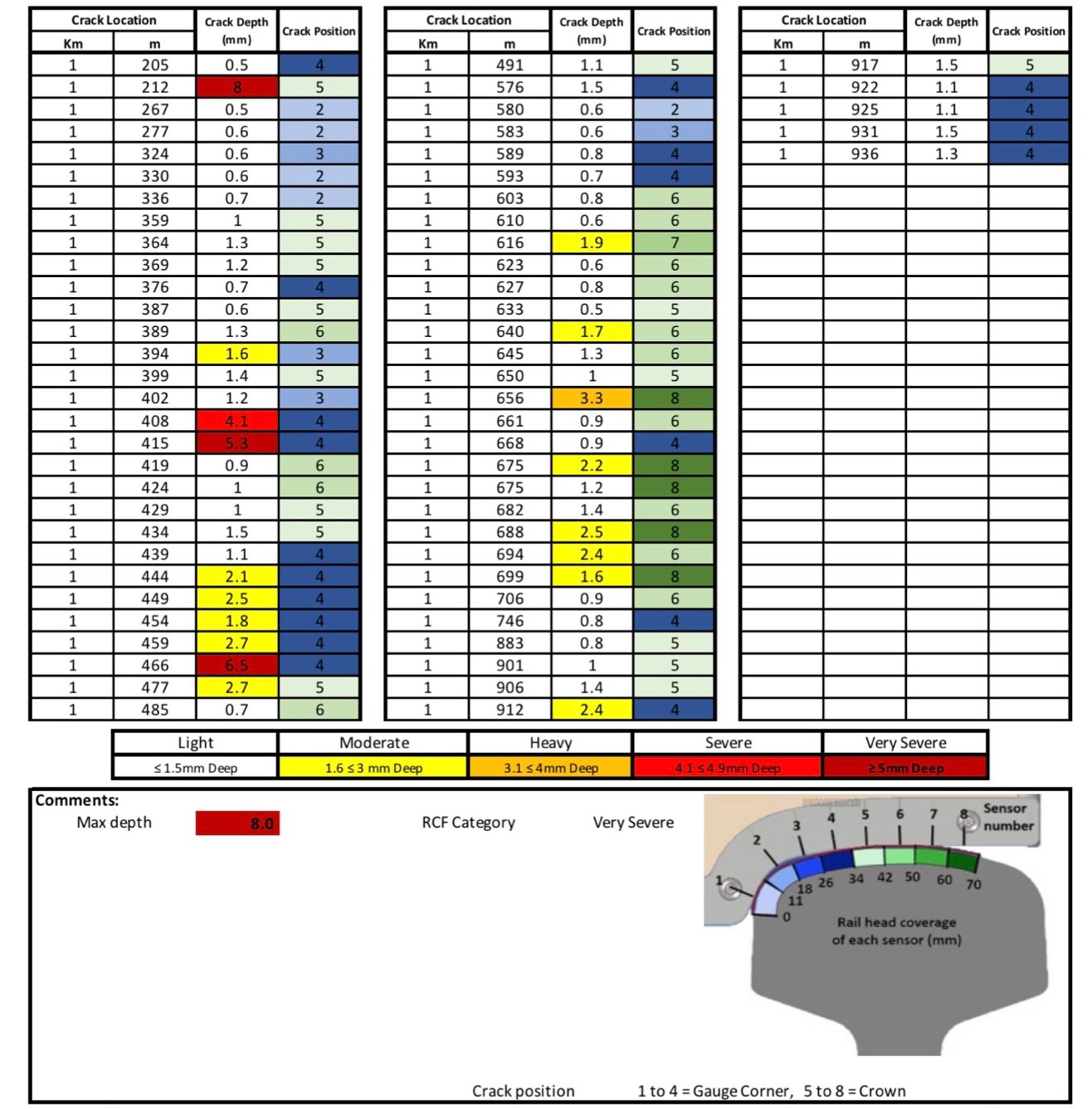

| Typical reporting range | 1-8+ mm |

| Detection and sizing depth range | 0.1-12 mm |

| Typical measuring speed | 3-6 kph |

| Track gauge | Variable 1000-1435-1520-1676 mm (other gauges optional) |

| Reporting output | Crack location, depth and classification Each crack measurement is given an individual ID number and a visual description Cluster RCF reported as deepest crack per meter |

TECHNOLOGY FROM THE LEADERS IN RAIL MEASUREMENT SYSTEMS

For Info:

info@railtechnology.com

Download