BI-CAT dual rail Corrugation Analysis Trolley

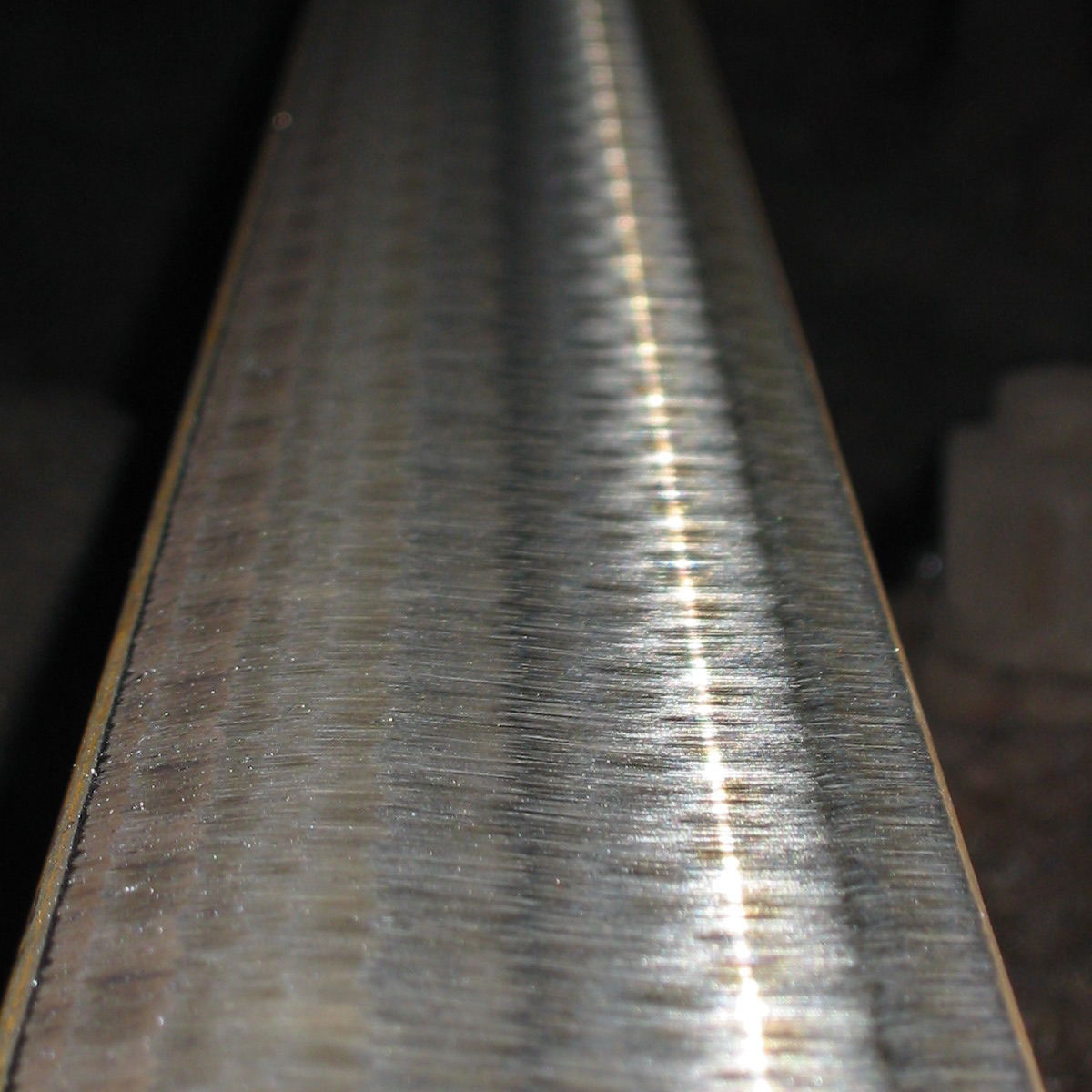

Rail corrugation and acoustic roughness measuring trolley for tracks and switches.

Suitable for vignola and grooved rails.

Product description:

Rail surface irregularities of the order of microns (0.001mm) in amplitude are important in the generation of wheel/rail rolling noise and vibrations. The CAT portable measuring trolleys is easy to carry and set-up and is suitable for obtaining continuous longitudinal measurements of irregularities on the rail surface.

BI-CAT

Applications:

- Monitoring of rail quality

- Detection of corrugation and acoustic roughness

- Detection and classification of both short and long waves

- Assessment of mobile rail treatment results e.g. rail grinding and milling

Main characteristics:

- Measurements that are highly accurate and repeatable

- Relatively simple installation and setup

- Contact measurement system using inertial sensors

- Suitable for any track gauge

- User-friendly software for acquisition and review of measurement data

- Operation through notebook or tablet-pc

- Robust yet light weight design

- Extensive product support

TECHNICAL DATA BI-CAT TROLLEY

| Interval at which data are saved | 1 or 2 mm | |

| Measuring speed | 3 - 4 kph | Walking speed |

| Precision of measurements | 0.01 µm (0.00001 mm) | Displacement |

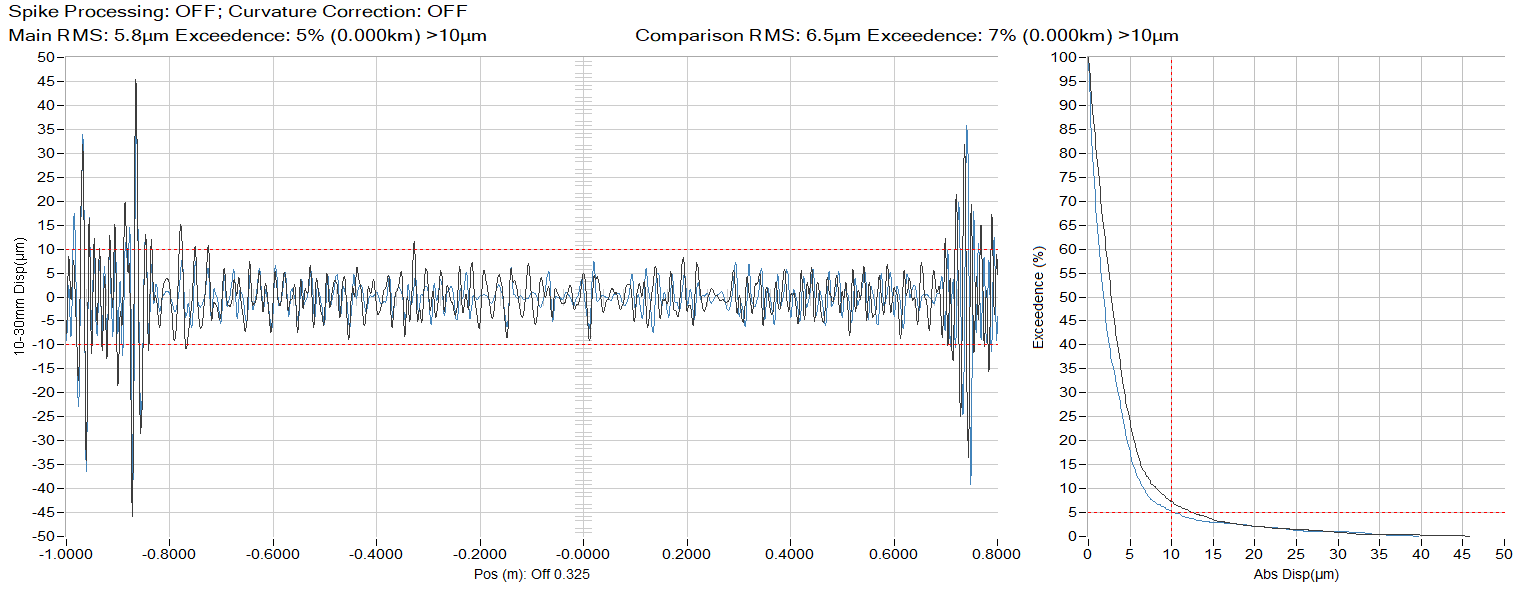

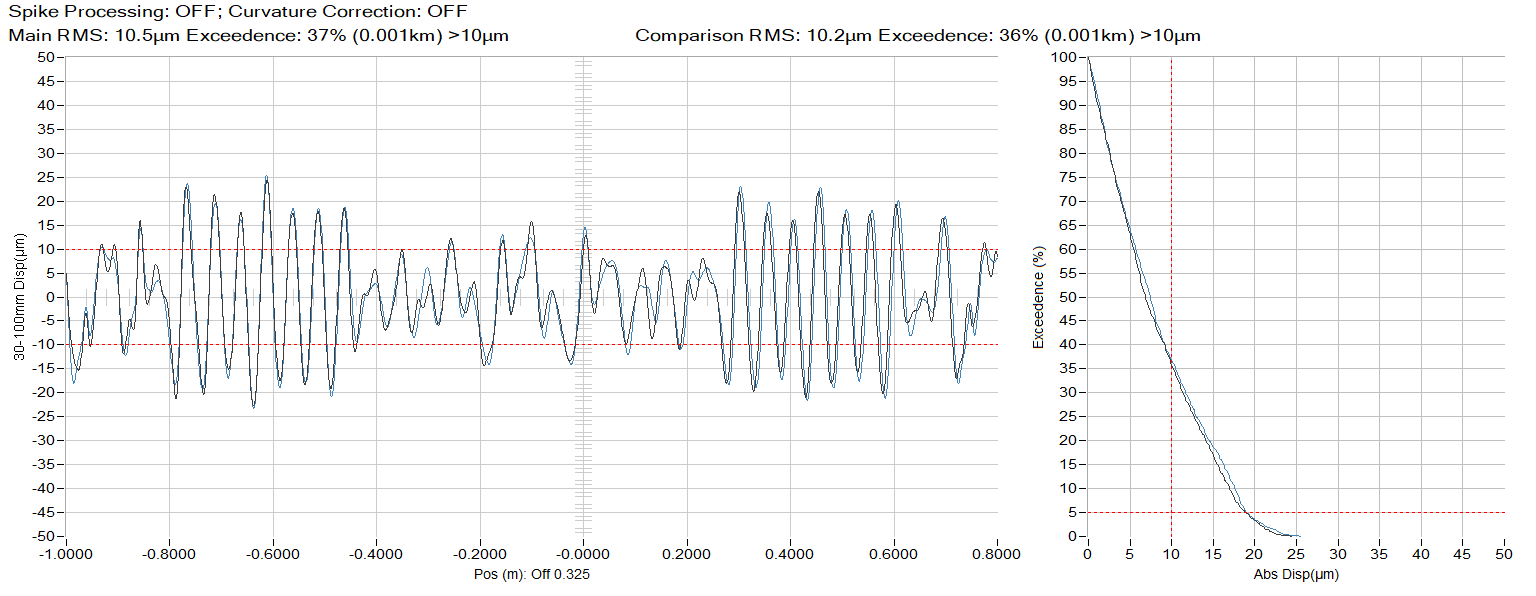

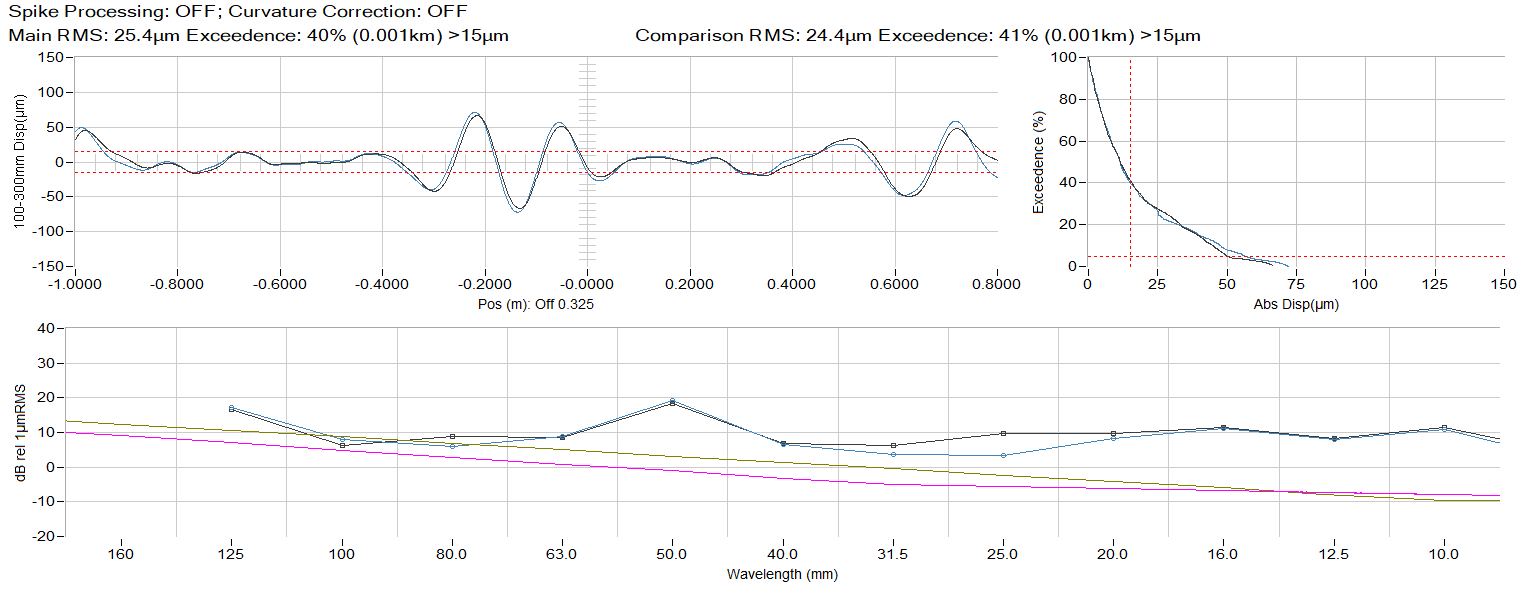

| Accuracy | 0.2 µm RMS 10 - 30 mm 0.5 µm RMS 30 - 100 mm 2 µm RMS 100 - 300 mm | |

| Data storage requirements | ~2 MB per KM of rail | |

| Output compatibility | EN 13231-2 2020 and equivalents EN ISO 3095:2013 EN 15610 | |

| Output | Raw and filtered displacements, moving average amplitudes, percentage exceedances, one third octave spectra | |

| Wavelength filters | 10 - 30, 30 - 100, 100 - 300, 300 - 1000, 1000 - 3000, 30 - 300, 300 - 3000 mm | |

| Weight | BI-CAT: 23 kg in carrying case |

TECHNOLOGY FROM THE LEADERS IN RAIL MEASUREMENT SYSTEMS

Typical calibration curves: BI-CAT and CMM measurements of a 1.8m section of a calibration beam.

For Info:

info@railtechnology.com

Download